Baldwin builds light-emitting diode (LED UV)-based curing solutions via its dedicated division, AMS Spectral UV - A Baldwin Technology Company.

The company proudly maintains the position as the world’s #1 manufacturer of industrial-strength UV LED curing solutions for wide-format offset printing applications, and for manufacturing and industrial use.

Meet Quatro Series™ LED-UV: For The Most Powerful Curing

The new Quatro Series™ LED-UV curing module is designed for industrial curing scenarios that require the highest power/greatest dose, and is also ideal for offset printing scenarios.

Utilizing numerous new market-leading features and patented “dual-optic” technology, the Quatro Series™ provides unprecedented system flexibility and reliability. Each module hosts two large, high-performance LED UV arrays, delivering double the available power of a standard LED solution at a lower cost than two individual lamps.

Learn more about AMS Spectral UV’s solutions for industrial curing in this brochure.

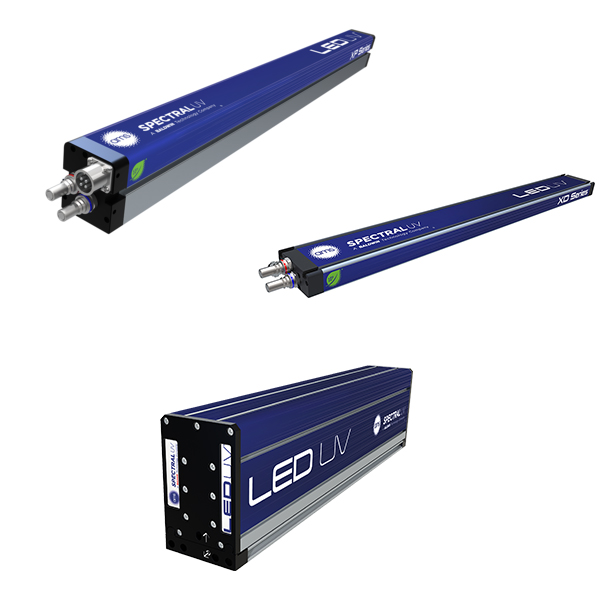

X Series LED™ - for Offset, Digital and Flexo

The X Series™ line of LED curing systems offers the world’s highest-power LED surface-curing solution at variable distances from the substrate. It is used to cure LED-formulated printing inks and coatings, and also in industrial curing scenarios where a reliable, elegant solution is needed to cure screen coatings and other layered composite materials.

How It Works:

X Series™ LED systems, manufactured by AMS Spectral UV - A Baldwin Technology Company, provide a simple, elegant way to cure inks as part of printing and industrial processes - they are most often used in sheetfed and web offset printing and larger-format flexography to achieve unparalleled quality of print at top speeds, on a variety of substrates including plastics, all with an eco-friendly process that eliminates mercury and VOCs from the picture.

Our solutions are also used for industrial curing scenarios that require seamless curing, without gaps due to “daisy-chain” module designs.

In operation, systems instantly turn on and off via operator controls - there is no warm-up time required, a key difference from other types of drying systems.

As the substrate passes under the LED light, special LED-reactive inks instantly cure, and achieve 100% dryness on the spot - printed work is immediately ready for the next processing step, be it the bindery or the customer.

Noteworthy Benefits:

Systems eliminate the need for spray powder because printed work is instantly dry

LED modules do not use mercury arc bulbs, so no mercury is present in the curing system

Newest-generation LED inks are the easiest to recycle, according to experts

Our “seamless” form factors achieve perfect surface-cure results, without risk of striping due to a daisy-chain design

LED curing is low temperature, so heat-sensitive substrates can be used without issue

Blade Series™ LED - For Flexo and Digital

The Blade Series™ LED-UV curing solution is ideal for narrow- and mid-width flexography, and well as for digital printing scenarios. It offers maximum curing power with a low-temperature process.

How It Works:

Blade Series™ LED systems, manufactured by AMS Spectral UV - A Baldwin Technology Company, offer a solution for narrower-web applications that require high-speed LED-UV curing; it can also be used for digital printing applications. Blade’s compact design is also ideal for certain industrial and manufacturing curing scenarios, where a narrow form-factor is ideal.

Noteworthy Benefits:

LED curing is a low-temperature process, so thin, heat-sensitive substrates can be printed on without issue

LED enables the fastest production speeds your press will allow

LED uses less electricity than other drying and curing methods

the Blade’s compact form factor fits in tight spaces, and is ideal for press setups with little space to spare