Baldwin’s flagship brand Ahlbrandt® is a world renowned manufacturer of corona treatment systems for printing and industrial applications such as film and sheet extrusion, and textiles.

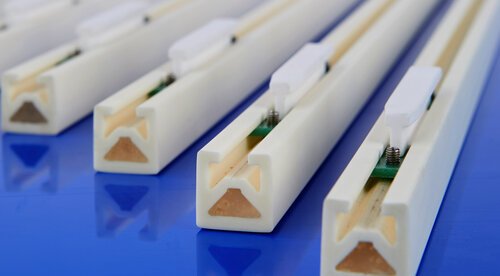

Our systems offer key features and benefits that set them apart from the competition by providing ease of service and reliability that is simply unmatched. A key differentiator: Ahlbrandt systems use four electrodes instead of the common “2-up” design, which dramatically improves treatment results.

How It Works:

Corona treatment systems work by increasing the surface energy of materials like plastic films, papers and foils, so that they can be printed on or coated with perfectly uniform results and effective adhesion.

Ahlbrandt’s premium quality German-made systems are known around the world as the leading corona treatment solution for the printing and film extrusion industries - they are also used in converting, narrow-web flexography, parts manufacturing and a host of other applications.

For years Ahlbrandt’s Corona systems has been the proven standard solution for the surface-wide handling of plastic films, metalized films, paper and textiles in Europe. Its unique “four-up” electrode design requires only one housing, a superior design feature that differentiates it from other solutions on the market.

Since Baldwin acquired Ahlbrandt in 2017, these products are now readily available and serviceable internationally, with ample product-support resources now established in the North American market.

Noteworthy Benefits:

Achieve the dyne levels needed for application of inks, coatings, etc. on nonporous substrates

Quick electrode changes and “cuttable” electrodes provide a unique advantage with Ahlbrandt corona systems

Corona Selection Guide

We have created a Corona Selection Guide to help you find the best Corona solution for your application and production line.

Ahlbrandt is well known for state-of-the-art, high-efficiency Corona systems designed for superior surface treatment in any areas of applications. Our technology can be found around the world enhancing the productivity in industries ranging from Print, Packaging, Film Extrusion & Converting, Paper, Panels, Sheets & Foams, Textiles & Nonwovens, Metal Plates and more.

We offer the market’s most efficient Corona systems with high-performance electrodes ensuring effective surface treatment for enhanced ink, coating, varnish and glue adhesion on a variety of materials. The slim design enables easy integration and retrofit into existing production lines, and our features allow for fast and easy service.

In addition to solving surface treatment problems for thousands of global industrial companies, Ahlbrandt is an authorized, strategic supplier to many OEMs. Our unique strengths are supported by constant innovations developed in our competence centers, as well as through implementation of the highest technical requirements – for safe, economical and future-proof surface treatments.

With Ahlbrandt Corona treatment

Without Ahlbrandt Corona treatment

Applications

Film production

Cast and blown film extrusion with and without longitudinal recess

Film finishing

Metalized and non-metalized films, thick-wall and heavy duty films, furniture films and edge bands, films on cardboard and paper after extrusion coating, printed films for subsequent coating, treatment refreshment for printing, coating and laminating, treatment with recess for subsequent sealing

Textiles and Nonwoven

Coating, laminating and finishing of synthetic fibers, printing and laminating of woven fabrics

Paper

Coating, laminating of coated paper and cardboard

Foam

High-density foams for adhesive tapes, insulating materials and composite materials

Metal foils

Printing, laminating, coating and ultra-fine cleaning of aluminum and copper foils

Molded parts, 3D parts

Marking of pipes and cables, bonding of molded parts, profiles, folding boxes and metal parts

Panels

Decorating of plastic and multi-wall panels, coating of glass panels

Our Corona Surface Treatment systems

Corona Pure

For years Ahlbrandt’s Corona Pure systems have been the proven standard solution for the surface-wide treatment of plastic films, metalized films, paper and textiles in Europe.

Corona Flex

Defined by high efficiency treatment, maximum uptime and easy maintenance, our Corona Flex is ideal for thick films and foams and guarantees optimized productivity and continuous quality in your production process.

Corona Slim

High performance in a small format is realized by the Corona Slim. This is a slim, simple and effective corona solution, designed by Ahlbrandt for easy installation and high efficiency in label and narrow web printing.

Corona Pure XL

The Corona Pure systems utilize a unique swiveling housing design enabling fast and easy maintenance, a feature that differentiates it from other solutions on the market.

Corona Extrude

Corona Extrude is especially innovated to maximize uptime, increase your productivity and deliver extensive pretreatment quality in blown film manufacturing.

Plasma 3D

For partial or non-flat shaped applications, our Plasma 3D solutions are ideal for increasing adhesion properties of small outlined areas – the Plasma JET can treat fields as small as 8 mm with high precision – and is highly efficient on a wide variety of materials. This, along with simple operation, easy installation on robot arms, freely movable in all directions, durable nozzle housings etc., makes our Plasma 3D innovations the most versatile of corona treatments.

Ahlbrandt’s generators offer exceedingly high energy efficiency and optimal performance. The modular design enables easy accessibility and simple replacement of components.

Customized solutions

Ahlbrandt designs and manufacture tailor-made Corona solutions for various materials, with total accuracy. To hint of the versatility of our technology, here are some examples of customized solutions we provided.

Foam Treatment

Bonding and laminating of foam / insulation panels

Materials on reels with thicknesses of 0.5 to 6 mm

Closed-cell foams with different thicknesses

Application examples – Foams for tapes, insulating materials for industry and real estate and automotive sectors.

Cable Treatment

Better printing, marking or coating of sheathing

Application examples – Cables, connections and hoses with and without electrical conductors.

Panel Treatment

Bonding, laminating, printing or coating non-flexible panel material

Continuously extruded material or separate panel material without thickness limit

Application examples – Decorative panels, solar modules, multi-wall panels, laminates, metal, wood and composite material.

Nonwoven Treatment

Optimized laminating, coating and finishing of technical textiles

Application examples – Membranes, filter materials, con-struction and safety textiles

Accessories

Easy Change

Short maintenance times – Easy Change, rapid electrode replacement without tools up to 2000 mm working width

Simple operation – Quick release of removable electrode system

Ozone Converter

Catalyst bed of metal oxides

Conversion of ozone (O3) into oxygen (O2)

No fire hazard (no activated carbon)

2 pre-filters for optimum catalyst protection

Monitoring of filter status

Easy and fast maintenance

DOWNLOAD OUR BROCHURE

Treat! With Superior Corona Efficiency

Ahlbrandt

With over 50 years of engineering expertise, Ahlbrandt is the pioneer of Corona pretreatment innovations in the surface treatment industry. Based in the heart of Germany and with a worldwide presence, Ahlbrandt designs and manufactures the world’s most efficient Corona treatment technology. Our experienced service technicians install and maintain your equipment all over the world and ensure a trouble free operation.

Your Benefits

Durability

Electrode Protection

Availability

Energy Efficiency

Perfect Uniformity