Baldwin is a key provider of IR drying technology for printing and other industrial applications.

We offer solutions for both sheetfed offset printing and for corrugated printing - if you are seeking an IR drying solution for another application, you can contact us to learn more about our engineering and manufacturing capabilities for this equipment type.

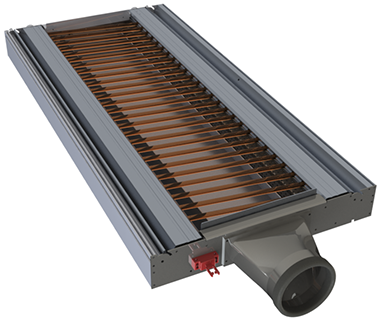

FlexoDry IR - for Corrugated Printing and Wide-Format Flexography

Baldwin has over 35 years of experience developing IR and hot-air drying solutions for industrial applications.

How It Works:

Designed for corrugated flexo printing presses, the FlexoDry infrared drying system is an ultra-efficient IR solution that delivers high-quality printing and significant productivity gains.

It uses infrared energy generated by patented Diamond IR lamps, and an optional integrated hot-air knife airflow system, to achieve perfect drying at top speeds.

FlexoDry systems can be retrofit onto existing presses, or integrated as part of a new press installation.

OPTIONS:

Available in modular widths of 150 mm cassettes

Two size variations for inter-station and end-of-press dryers

Integrated controls on new presses for streamlined operation

Compact design with no ducting

Noteworthy Benefits:

Reduced energy consumption with the use of Diamond IR lamps and other features

Uses less energy than traditional IR drying systems

Dramatically improved drying enhances color definition and reduces or eliminates marking while allowing full-speed printing

full customer service and support structure to keep you running smoothly for years to come

Free Webinars:

Top Three Technologies for Corrugated in 2021

Corrugated Market Needs and Technologies

Automated Cleaning - the next level in Corrugated

Drying Efficiency in Corrugated

GraphiSet 4 - for Sheetfed Offset

GraphiSet 4 is designed for sheetfed offset (SFO) presses with inline coaters, that normally print gloss or matte coatings on brochures, magazines, packaging etc.

How It Works:

When printing with conventional inks and water-based coatings, it is necessary to heat the inks and simultaneously remove water from the coating. GraphiSet’s combination of infrared radiation, hot air and and efficient exhaust system enables sheets to be dried at full press speeds - despite incredibly short dwell time.

Automatic Temperature Control (ATC) is provided via sensors that measure the thermal energy of the sheet in the delivery, without contact. Job settings like ATC, air-knife temperature, air volumes and sheet size can be stored in the HMI for repeat jobs.

Noteworthy Benefits:

Provides automatic temperature control

Operators have the ability to store job information

Quick start, low-maintenance system

Air used for cooling is recycled and used in the drying process